Laboratory & quality.

AURORA has an excellently equipped and TDAP-accredited laboratory for carrying out measurements in the field of light technology. Compliance with our own and our customer’s high quality standards for AURORA products is regularly checked in the laboratory and production department. We deliver quality “Made in Germany”.

Accredited laboratory

The laboratory’s accreditation means we can participate in the VDE TDAP procedure for standards 62560 (safety standard) and 62612 (performance standard) for LED bulbs. All calibration standards are calibrated by external laboratories according to ISO 17025 with Dakks certificates.

Procedural steps for maximum quality

ULBRICHT SPHERE

The electrical and photometric data of our lights can be determined using photometric measurements carried out with the Ulbricht sphere.

Measurement data:

- Luminous flux

- Colour temperature

- Electrical power

- Voltage

- Current

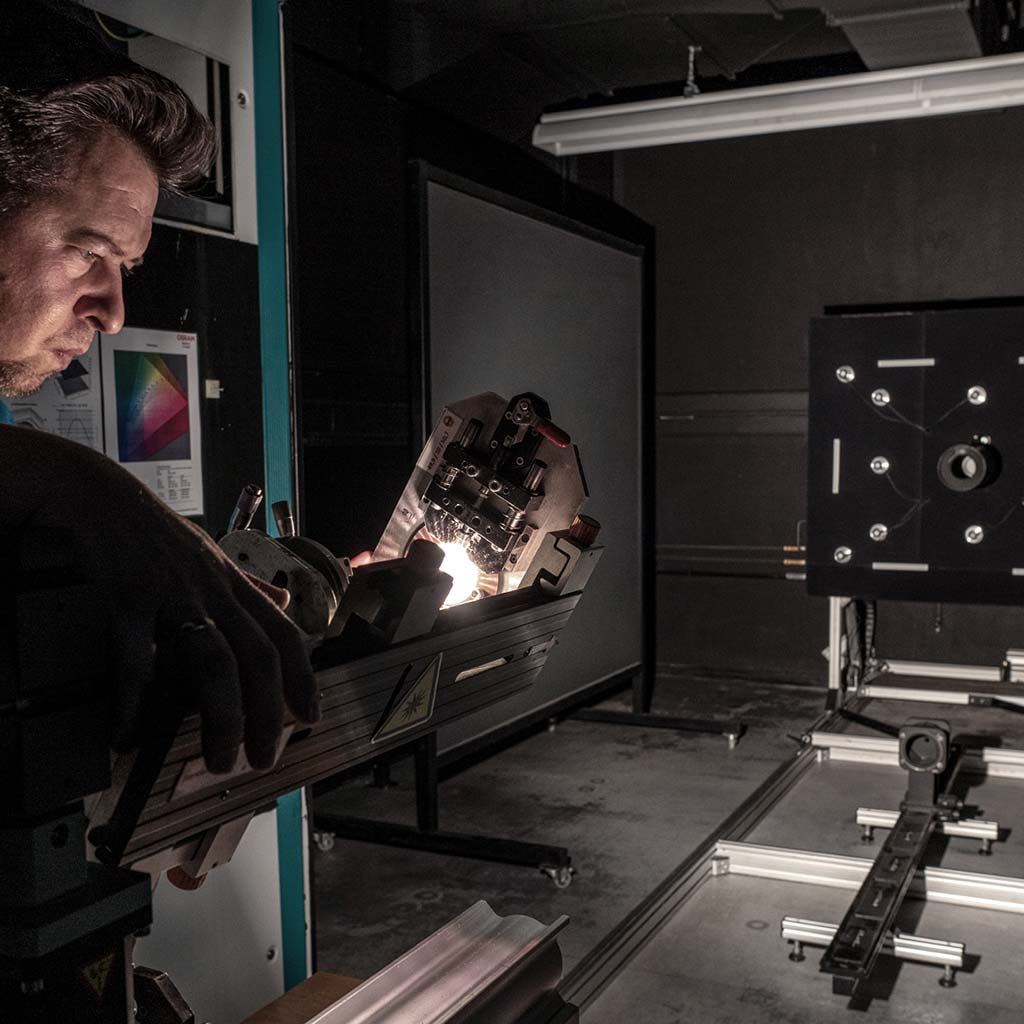

GONIOMETER

Goniometer measurements determine the technical lighting data and light distribution curves of our lights.

Measurement data:

- Electrical bulb data

- Axial light intensity

- Luminous flux

- Light distribution curves

X-RAY

This measuring device allows us to geometrically measure assemblies in the “closed” state using X-rays. In addition, detail recognition can be optically checked in the micrometre range.

Measurement data:

- Length

- Angle

- Surface ratio

OUTER GEOMETRY

Contactless, high-precision 3D surface measurements can be carried out using a profilometer. Structures and component roughness can be geometrically measured in the micrometre range.

Measurement data:

- Length

- Width

- Height

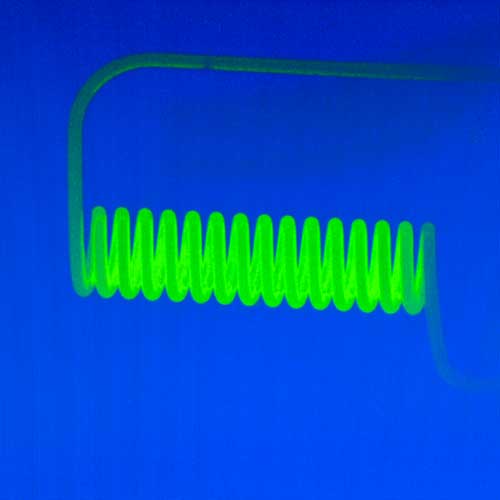

INNER GEOMETRY

This measuring method is used to measure the filament in the bulb. Applications include the automotive, signal and general lighting sectors.

LUMINOUS DENSITY

Using this optical measurement, we can determine the luminance distribution of bulbs. Applications include, for example, the automotive sector.

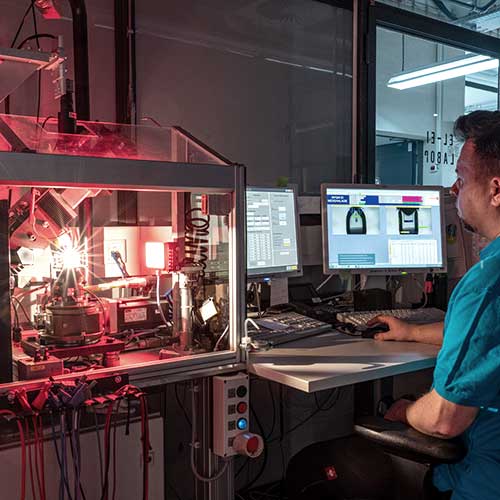

LIFE AND STRESS TEST

In the “combustion chambers and cabinets”, life tests and stress tests are simulated on the bulbs using a wide variety of switching cycles and conditions such as heat, humidity and thermal shock.

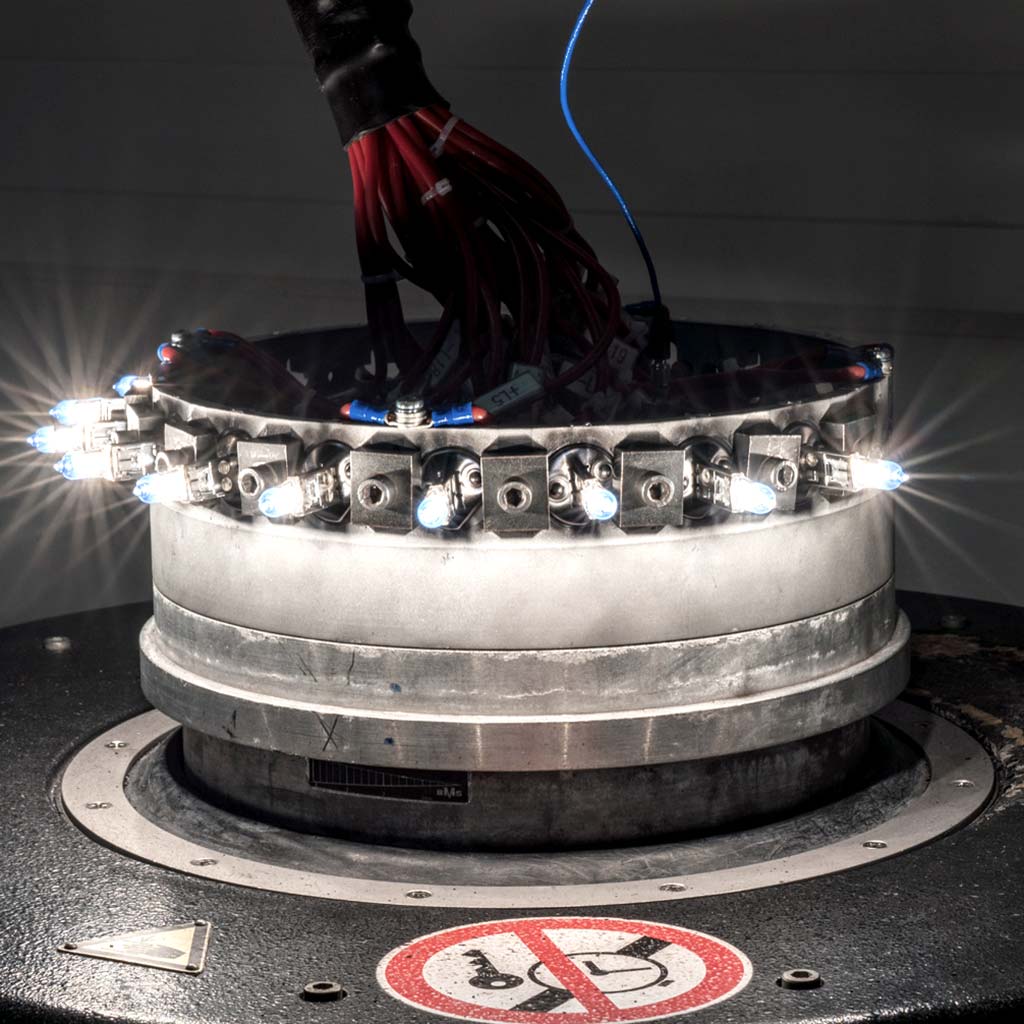

VIBRATION TEST

This system is used to check the vibration resistance of bulbs. The tests can be carried out in a frequency range of 0 – 3000 Hz and at a maximum acceleration of 556 m/s2.

Do you have any questions about the subject of laboratory & quality?

Then please feel free to contact us!

Our specialists will be happy to provide you with more information.

Thinking and acting with quality in mind are essential components of our corporate policy.