Production.

AURORA Lichtwerke produces light sources, lights and complete lighting systems – Made in Germany. Traditional light sources and products for modern LED lighting solutions are produced on a small and large scale using our production facilities.

Experience and innovation

With our technological expertise and the experience of our manufacturing and automation employees, we are able to manufacture our products using automated, stable and reliable manufacturing processes.

The production steps for maximum quality

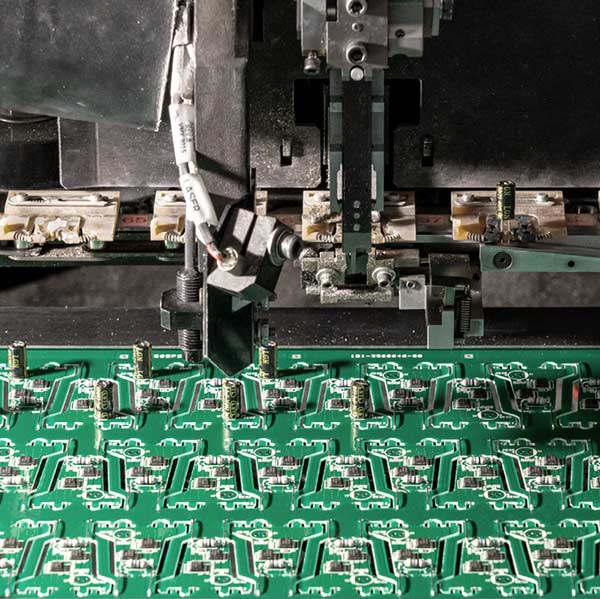

ELECTRONICS – FULLY AUTOMATIC THT MOUNTING (THROUGH-HOLE TECHNOLOGY)

Fully automatic THT mounting involves fitting wired electronic components to PCBs (printed circuit boards). The axial, radial and special components can also be bent into the intended positions during the automatic mounting process.

ELECTRONICS – FULLY AUTOMATIC SMD MOUNTING

SMD components such as LEDs can be mounted on the top and bottom of the PCB using fully automatic processes. Optical controls, such as AOI and SPI, check the solder paste application and ensure the components are positioned correctly and completely on the PCB. We use reflow and wave soldering processes.

ELECTRONICS – LONGBOARD LINE

On this special mounting system, electronic components can be mounted on to PCBs up to 1600 mm in length.

ELECTRONICS – FUNCTIONAL AND OPTICAL MEASURING SYSTEMS

In order to ensure the quality of the assembled electronic components, every production system has optical measuring systems (Automatic Optical Inspection / Solder Paste Inspection) and electrical function controls.

PRODUCTION OF LED BULBS

The electronics modules are combined with mechanical components on the fully automated assembly lines. Our experience of connections such as glass-to-glass, glass-to-metal and metal-to-metal, which are used in traditional bulb production, comes in useful here. The assembly systems have electronic and optical measuring systems that guarantee the quality of our products.

THERMAL FORMING AND PROCESSING OF GLASS

Fully automated production systems with a high adjustment performance shape quartz glass tubes into bulbs for our bulb production. The different geometries of the glass bulbs are fully checked using optical measuring systems integrated into the production facilities.

PRODUCTION OF HALOGEN, SPECIAL AND SIGNAL BULBS

Traditional bulbs are largely produced on high-performance production systems for halogen bulbs in the low, medium and high-voltage range. Due to the high degree of automation, quantities of over 6000 bulbs per hour can be achieved. Special purpose and signal bulb construction produces lighting solutions for special areas of use such as medicine, airport lighting and high temperatures. Online measuring systems are integrated into all production facilities to ensure the quality of our products.

COATING

With our sputtering system, materials can be coated with interference layers for colour filters, reflective layers, selective filters and layers for surface protection.

Do you have any questions about production?

Then please feel free to contact us!

Our specialists will be happy to provide you with more information.

Thinking and acting with quality in mind are essential components of our corporate policy.